Sarah Jefferson

Vandersanden, Belgium based, largest brick manufacturer in Europe.

Focus on sustainability and innovative, future orientated brick products

Carbon neutral factories, carbon negative bricks

Brick introduction

A perfect natural blend of the four elements, made out of clay.

- Frost resistent

- durable

- cost efficient

- fire resistent

- reusable/recycable,

- various colours/textures.

Sustainability:

- Rainwater is used, where possible

- Crushing of bricks to use in filling material, allows the brick to be recycled.

- Almost maintenance free

Clay is formed naturally over many years

Local geology influences the clay color

Main brick types:

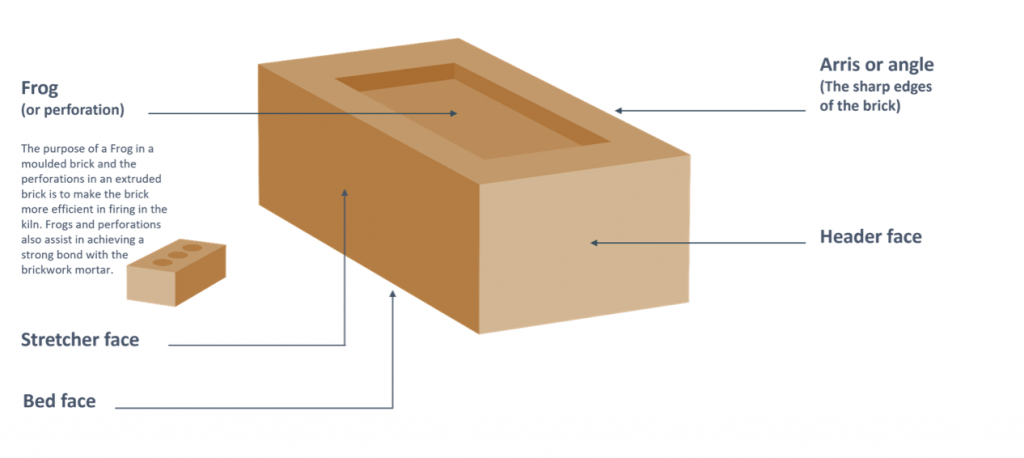

Stock (handform)

- Hand and machine made

- Typically includes a frog depression in bed face

Water-struck

- Slightly textured appearance

- Soft, glazed character

- Lip and vertical lines, from water release

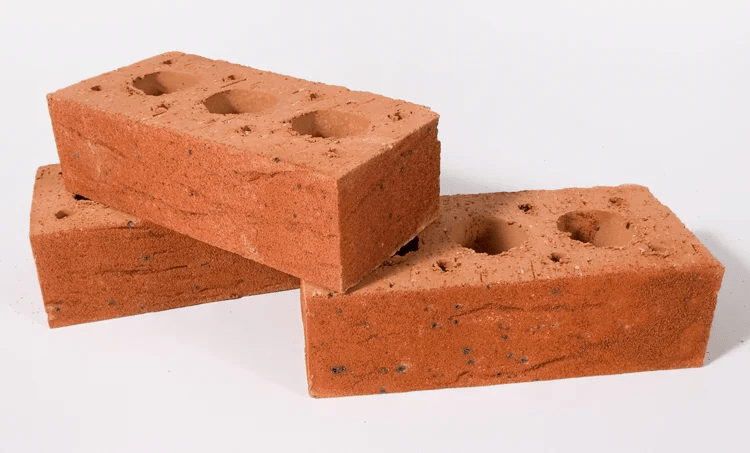

Wire-cut

- A relatively smooth appearance

- Perforated bed face

- Angular crisp arris

- High tolerance and easy to cut

Brick terminology:

Stretcher Bond

English Bond

Flemish Bond

Stack or tiled Bond

Important considerations when selecting bricks:

- Durability – Frost resistance ratings -> F0-F2 Ratings

- Minerals and active soluble salts -> S0-S2 Ratings

- Bricks below damp proof course level

- Cavity wall insulation -> min 50mm air space between brick and insulation

- Configuration and brick size -> UK standard size: 215×102.5x65mm -> different to CH (150/175/200)

- Co-ordinating size (ex. standard): 225×112.5x75mm -> Including mortar joint

- Mortar joint profiles: Bucket handle (only one I used in practice), Weather struck, Flush, Recessed

Difference mortar color can make on a brick wall

A Limit of brick laying of 1200mm a day is recommended!

This avoids possible mortar displacement.

Building movement:

- Movement joints -> no more than 3m to the first from corner, after that every 6m. (free standing wall), Building wall the distance from the corner should not extend 6m.

What struck me most about today’s session was the direct comparison of approaches to using brick as a building material between the UK and Switzerland.

Many of the requirements or recommendations differ from the Swiss standards I learned during my training as a draftsman in structural engineering.

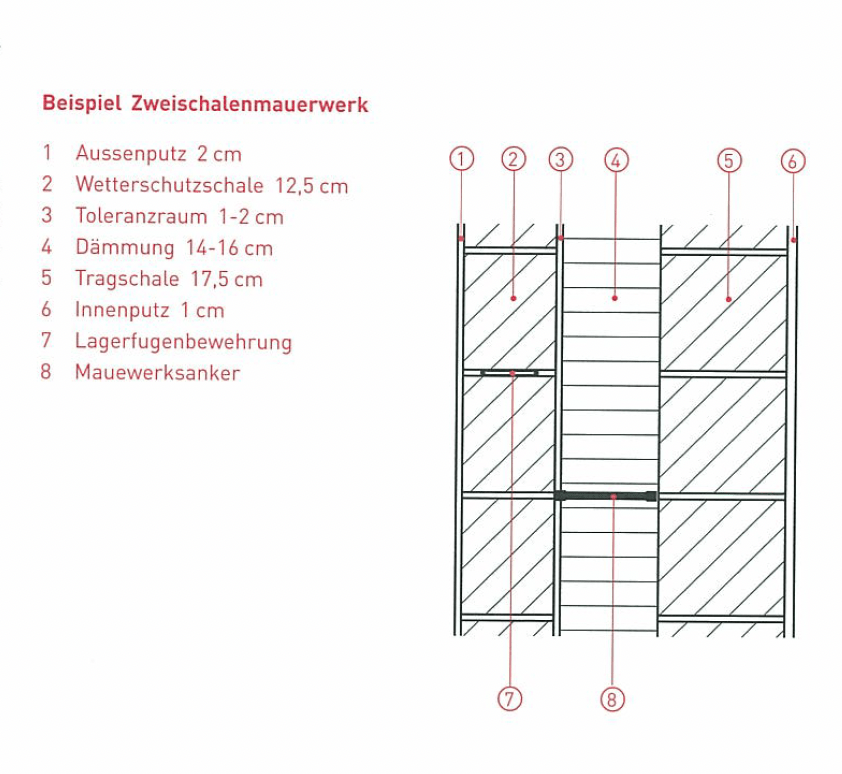

Example: a detail of a cavity wall construction from my Swiss course material.

I found it remarkable how the tolerance space behind the outer brick wall differs so greatly—just 10–20 mm in Switzerland compared to the recommended 50 mm in the UK. The standard dimensions of Swiss bricks also deviate considerably from the UK norm, most likely because the “common” Swiss dimensions refer to bricks that are usually plastered or integrated into a ventilated wall system.

Another striking point is how brick, especially as exposed masonry, appears to be much more widespread and historically rooted in the UK than in Switzerland. Apart from old factories or in some cases farmhouses, historical examples of exposed brickwork are rarely found in my home region.

The regulations concerning the spacing of the vertical elements of fall protection barriers also differ. In Switzerland, the maximum permitted distance is 12 cm, whereas in the UK it is only 10 cm!

Leave a comment